1.New sintering process: new power to improve the quality of permanent magnet materials

The new sintering process is a very important part in the production of permanent magnet materials. In terms of magnetic properties, the new sintering process can significantly improve the remanence, coercive force and maximum magnetic energy product of permanent magnet materials. Research shows that using advanced new sintering processes, the remanence and coercive force of permanent magnet materials will be significantly improved. In terms of mechanical properties, the new sintering process also has a positive impact. It can enhance the hardness, strength and toughness of permanent magnet materials, making them more durable and reliable. The permanent magnet material processed by the new sintering process can withstand greater external impact and wear, extending the service life.

Hangzhou Magnetic Juli Technology Co., Ltd. has significant advantages in new sintering processes. The company has a professional R&D team that constantly explores innovative sintering process technologies. By introducing advanced equipment and intelligent control systems, various parameters in the sintering process are precisely controlled to ensure that each batch of permanent magnet materials can meet high quality standards. At the same time, the company focuses on cooperation with domestic and foreign scientific research institutions, actively draws on advanced technological experience, and continuously improves its core competitiveness. With its excellent new sintering process and strict quality control system, the permanent magnet materials produced by Hangzhou Magnetic Juli Technology Co., Ltd. have won widespread praise and recognition in the market.

2. Characteristics of the new sintering process

(1) Rapid heating and uniform temperature

New sintering processes often use medium frequency induction furnaces for sintering. The medium frequency induction furnace has the distinctive feature of fast heating speed and can reach the required sintering temperature in a short period of time. This not only improves production efficiency but also reduces energy consumption. At the same time, the internal temperature of the material in the medium frequency induction furnace is uniform. This is because the principle of induction heating causes the molecules inside the material to be heated by electromagnetic induction at the same time, thereby avoiding the temperature gradient that may occur in traditional heating methods. Uniform temperature distribution helps the material form a more uniform and dense crystal structure to avoid stress concentration, thereby improving the magnetic and mechanical properties of permanent magnet materials.

(2) High efficiency and energy saving

The new sintering process excels in terms of efficiency. Due to the fast temperature rise and short sintering time, it can complete the sintering process in a shorter time than traditional sintering furnaces. This not only improves production efficiency but also reduces energy consumption. The characteristics of high efficiency and energy saving enable enterprises to reduce costs and improve competitiveness in the production process. At the same time, this is also in line with the current development trend of energy conservation and environmental protection and contributes to sustainable development.

(3) Combination of rapid cooling and tempering

In the new sintering process, the rapid cooling and tempering processes after sintering play a key role in improving product quality. Rapid cooling can quickly cool down the material and inhibit grain growth, thereby obtaining a finer and more uniform grain structure. Tempering can eliminate residual stress inside the material and improve the toughness and stability of the material. Through the combination of rapid cooling and tempering, the comprehensive performance of permanent magnet materials has been significantly improved. Hangzhou Magnetic Juli Technology Co., Ltd. makes full use of this process feature to continuously optimize the production process and provide customers with high-quality permanent magnet material products.

3. Key factors of permanent magnet material quality

(1) Effect of temperature

Temperature plays a crucial role in the performance stability of permanent magnet materials. The magnetic properties of permanent magnet materials change with temperature. When the temperature increases, the remanence and coercive force of permanent magnet materials usually decrease. This is because rising temperature will cause changes in the magnetic domain structure inside the permanent magnet material, thus affecting its magnetic properties. In addition, temperature changes may also cause thermal expansion and contraction of the permanent magnet material, causing stress, which further affects its performance stability. Therefore, during the production and use of permanent magnet materials, the temperature must be strictly controlled to ensure stable performance.

(2) Magnetic field and mechanical stress

Magnetic field strength, direction and mechanical stress also have an important impact on permanent magnet materials. The strength of the magnetic field directly determines the degree of magnetization of the permanent magnet material. When the magnetic field intensity increases, the degree of magnetization of the permanent magnet material also increases, thereby improving its magnetic properties. However, too high a magnetic field intensity may cause irreversible changes in the magnetic domain structure of the permanent magnet material, reducing its performance stability. The direction of the magnetic field also affects the performance of permanent magnet materials. Different magnetic field directions will cause the magnetic properties of permanent magnet materials to show different characteristics. Mechanical stress also affects permanent magnet materials. When a permanent magnet material is subjected to mechanical stress, its internal crystal structure may deform, thus affecting its magnetic properties.

(3) Oxidation and impurities

The impact of oxidation and impurities on the quality of permanent magnet materials cannot be ignored. Oxidation causes an oxide layer to form on the surface of the permanent magnet material, reducing its magnetic properties. In addition, the presence of impurities will also affect the performance of permanent magnet materials. Impurities may damage the crystal structure of permanent magnet materials, causing a decrease in their magnetic properties. Therefore, in the production process of permanent magnet materials, strict anti-oxidation measures must be taken and the purity of raw materials must be ensured to improve the quality of permanent magnet materials.

(4) Magnetization process and aging effect

The magnetization process and aging effects also play an important role in the performance of permanent magnet materials. The choice of magnetization process will directly affect the magnetization degree and magnetic properties of the permanent magnet material. Different magnetization processes will cause the magnetic properties of permanent magnet materials to show different characteristics. The aging effect means that the properties of permanent magnet materials will change after a period of use. Aging effects may cause the residual magnetism and coercive force of permanent magnet materials to decrease, thus affecting their performance stability. Therefore, when selecting the magnetization process and using permanent magnet materials, the influence of aging effects must be considered to ensure stable performance.

Hangzhou Magnetic Juli Technology Co., Ltd. is fully aware of the impact of these key factors on the quality of permanent magnet materials. By strictly controlling factors such as temperature, magnetic field, oxidation and impurities during the production process, it adopts advanced magnetization processes and conducts strict quality inspection on its products. Quality inspection and aging processing ensure that we provide customers with high-quality permanent magnet material products. The company’s professional technology and strict quality control system make it stand out in the permanent magnet material industry and become a trusted partner of customers.

4. Advantages of Hangzhou Magnet Technology

(1) Strong scientific research team

Hangzhou Magnetic Juli Technology Co., Ltd. was established by a team of magnetic materials experts from the Chinese Academy of Sciences and has strong strength. The company has many doctors and masters, who have profound academic attainments and rich practical experience in the field of magnetic materials. The addition of these professionals provides strong intellectual support for the company’s technological innovation and product research and development. They continue to explore new sintering processes and are committed to improving the quality and performance of permanent magnet materials to provide customers with better products.

(2) Superior geographical location

The company is located in Hangzhou, a vibrant city with a strategic location. There are ports nearby and transportation is convenient, which provides great convenience for the company’s raw material procurement and product sales. At the same time, Hangzhou, as a highland of scientific and technological innovation, has a good business environment and rich human resources, which provides a strong guarantee for the company’s development.

(3) Multiple patented technologies

Hangzhou Magnetic Juli Technology Co., Ltd. has obtained a number of invention patents in the field of rare earth permanent magnet materials. These patented technologies cover every aspect from material preparation to product application, making it possible to meet customers’ customized needs. In addition, the company also actively carries out industry-university-research cooperation, cooperates with domestic and foreign universities and scientific research institutions to carry out technology research and development, and continuously improves the company’s technical level and innovation capabilities.

(4) Focus on high-end products

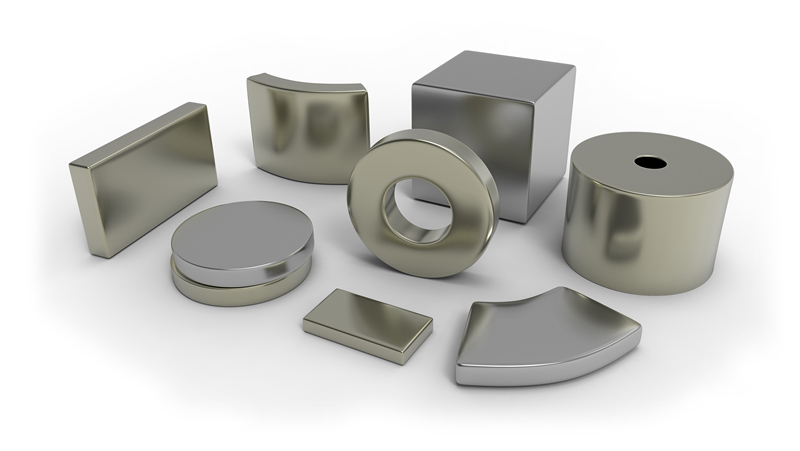

The company is committed to the research and development, production and sales of high-end rare earth permanent magnet materials and devices. In terms of product research and development, the company invests a lot of manpower, material resources and financial resources to continuously launch products with high performance and high reliability. The company’s high-end products are widely used in aerospace, new energy vehicles, medical equipment and other fields, providing important support for the development of these fields.

(5) Application of new sintering technology

Hangzhou Magnetic Juli Technology Co., Ltd. actively applies new sintering processes, such as the rapid sintering method of samarium cobalt magnets, to continuously improve product quality. The company’s new sintering process has the advantages of fast heating, uniform temperature, high efficiency and energy saving. It can make the crystal structure of permanent magnet materials more uniform and dense, thereby improving its magnetic and mechanical properties. In addition, the company also focuses on the continuous optimization and improvement of new sintering processes to meet customers’ higher requirements for product quality.

5. Future development

The new sintering process has undoubtedly brought many positive effects to the quality of permanent magnet materials. By precisely controlling temperature and time, the crystal structure of the permanent magnet material is uniformly dense and the magnetic properties are greatly improved, such as residual magnetism, coercive force and maximum magnetic energy product. At the same time, in terms of mechanical properties, the hardness, strength and toughness of the permanent magnet material are enhanced, making it more durable and reliable, and extending its service life.

Hangzhou Magnetic Juli Technology Co., Ltd. plays a leading role in the industry with its significant advantages in new sintering processes. A strong scientific research team continues to explore and innovate. Its strategic location brings advantages in transportation and human resources. A number of patented technologies meet the customized needs of customers. It focuses on high-end products to provide support for important fields and actively applies new sintering processes to improve product quality.

Looking to the future, with the continuous advancement of science and technology and the continued growth of market demand, the application of new sintering processes in the field of permanent magnet materials will become more extensive and in-depth. Hangzhou Magnet Technology is expected to continue to lead the development of the industry, continuously optimize new sintering processes, and improve production efficiency and product quality. Under the general trend of environmental protection and energy conservation, the company will further reduce energy consumption and make greater contributions to sustainable development. At the same time, with the vigorous development of high-end manufacturing, the demand for high-performance permanent magnet materials will continue to increase. Hangzhou Magnet Technology’s high-end products will play a more important role in aerospace, new energy vehicles, medical equipment and other fields.

Post time: Nov-08-2024